Gd And T Surface Finish

Surface finish cheat sheet.

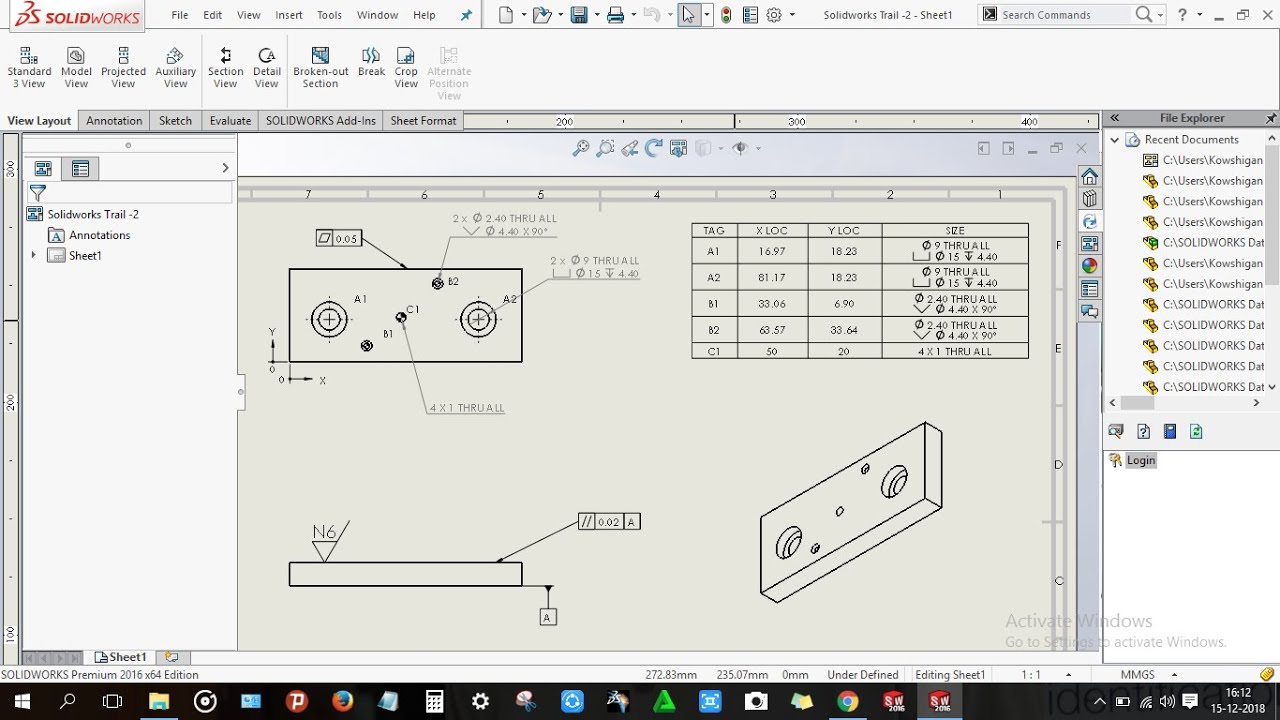

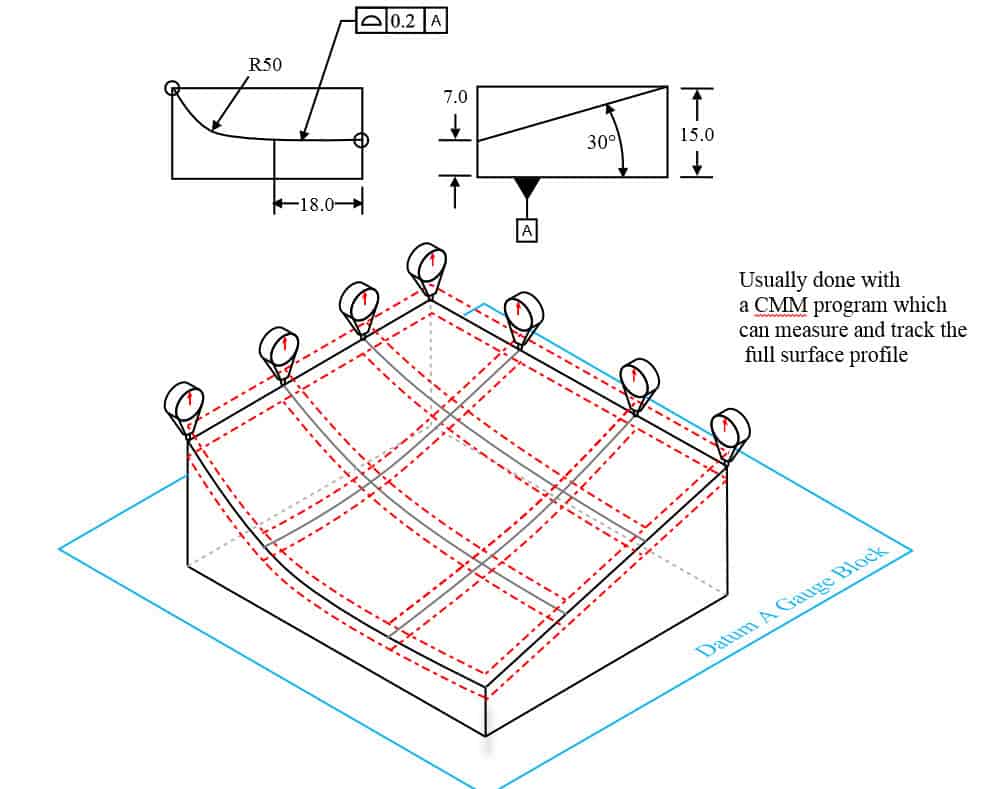

Gd and t surface finish. Usually when surface profile is required there are no tolerances on the dimensions that describe the surface and use the gd t callout to give the acceptable range. Factors affecting surface finish. The details in iso surface finish standards relate to surfaces produced by abrading casting coating cutting etching plastic deformation sintering wear erosion and some other methods. Surface finish roughness casting die casting good 1 2µm investment good 1 5 3 sand casting poor 12 25 metal forming cold rolling good 1 3 hot rolling poor 12 25 machining boring good 0 5 6 drilling medium 1 5 6 milling good 1 6 turning good 0 5 6 abrasive processes grinding very good 0 1 2.

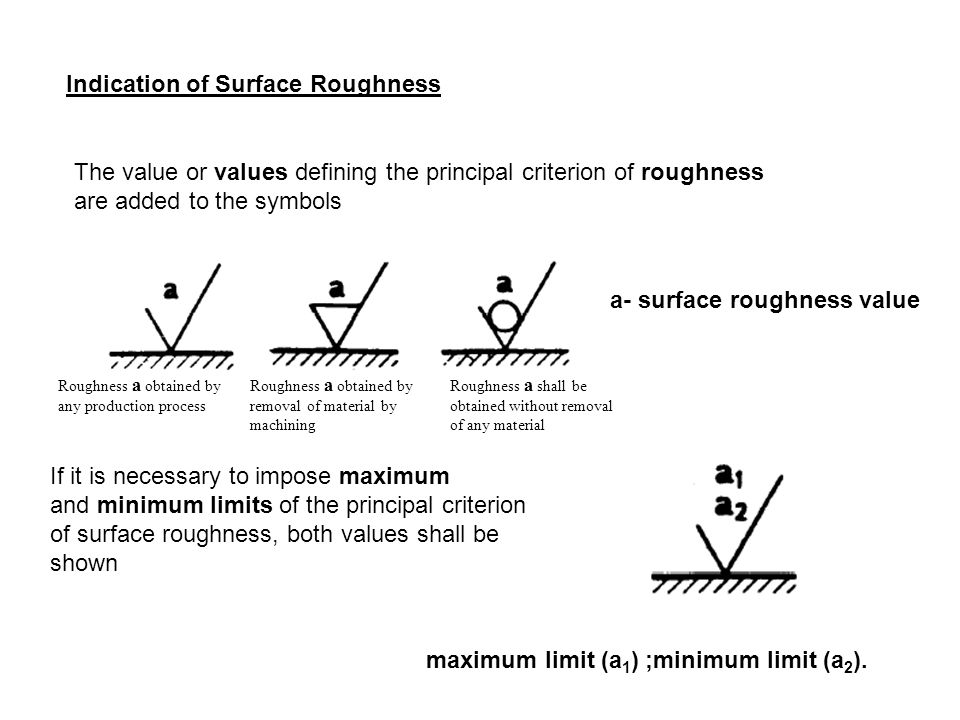

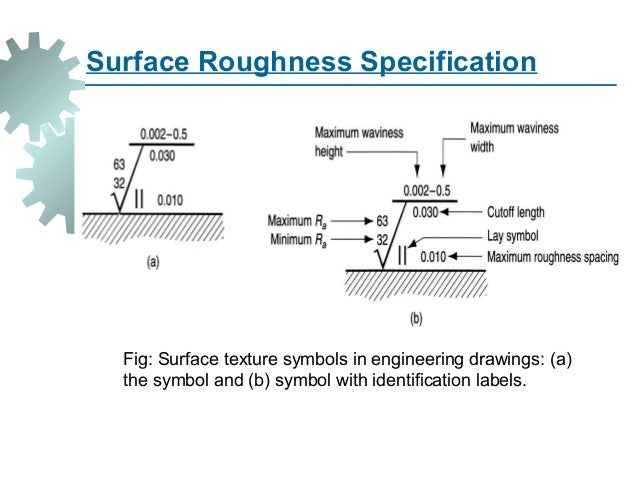

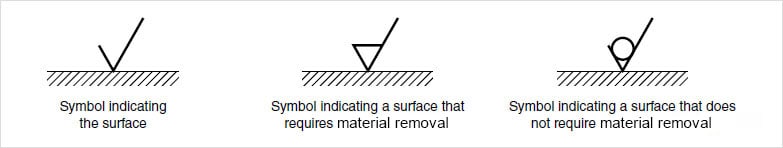

Size of forms and shapes of features. 3 dimensional tolerance zone existing of 2 parallel surface curves that follow the contour of the surface profile across the entire length of the surface. Currently the gd t standard is defined by the american society of mechanical engineers asme y14 5 2018 for the usa and iso 1101 2017 for the rest of the world. To specify surface finish use either the iso or ansi symbols.

There are many factors that affect surface finish with the biggest being the manufacturing process see table above. Surface finish symbols and callout example. Gd t flatness is a common symbol that references how flat a surface is regardless of any other datum s or features. Geometric dimensioning and tolerancing gd t is an accurate technique for defining and controlling the.

Someone will be along soon to finish this section. Surface finish cheat sheet. The principal iso standard that specifies syrface roughness is iso 1302 and defines the surface roughness symbology and additional requirements for engineering drawings. A super handy surface finish cheat sheet.

The size and geometric tolerances. It comes in useful if a feature is to be defined on a drawing that needs to be uniformly flat without tightening any other dimensions on the drawing. Gd t specifies parameters like flatness but these are not really surface finish. It concerns mostly the overall geometry of the product while other standards describe specific features such as surface roughness texture and screw threads.

There are many factors that affect surface finish with the biggest being the manufacturing process see table above.